|

Ningbo Xinqi Precision Magnetism Steel Co., Ltd

|

Motor magnet countersunk in ring

| Payment Terms: | T/T,L/C |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Neodymium Magnets N45SH

Size: OD15*ID 3.3/6.5*3.5mm

Coating: Nickle (thickness ≥15μm) Ni+Cu+Ni 3 Layer coating, the BEST coating.

Product: Countersunk motor NdFeB magnet 45SH

Features:

1) This kind of countersunk magnet widely used in motor.

2) Size: OD15*ID 3.3/6.5*3.5mm

3) Grade: 45SH

4) Coating: Nickle (thickness ≥15μm) Ni+Cu+Ni 3 Layer coating, the BEST coating available

5) Magnetized Direction: through thickness

6) Applications: motors

Packing:

Inner packing: small white box, place plastic between magntes to avoid breaking.

Outer packing: Carton with OPP bag

Properties:

| Sintered Nd FeB magnetic properties | |||||||||

| (Hcb) | (Hcj) | (BH)max | Max Working | ||||||

| Grade | mT | kGs | kA/m | kOe | kA/m | kOe | kJ/m³ | MGOe | Tempt(TW)℃ |

| N35 | 1170-1220 | 11.7-12.2 | ≥868 | ≥10.9 | ≥955 | ≥12 | 263-287 | 33-36 | 80℃ |

| N38 | 1220-1250 | 12.2-12.5 | ≥899 | ≥11.3 | 287-310 | 36-39 | |||

| N40 | 1250-1280 | 12.5-12.8 | ≥907 | ≥11.4 | 302-326 | 38-41 | |||

| N42 | 1280-1320 | 12.8-13.2 | ≥915 | ≥11.5 | 318-342 | 40-43 | |||

| N45 | 1320-1380 | 13.2-13.8 | ≥923 | ≥11.6 | 342-366 | 43-46 | |||

| N48 | 1380-1420 | 13.8-14.2 | ≥923 | ≥11.6 | 366-390 | 46-49 | |||

| N50 | 1400-1450 | 14.0-14.5 | ≥796 | ≥10.0 | ≥876 | ≥11 | 382-406 | 48-51 | |

| N52 | 1430-1480 | 14.3-14.8 | ≥796 | ≥10.0 | 398-422 | 50-53 | |||

| 35M | 1170-1220 | 11.7-12.2 | ≥868 | ≥10.9 | ≥1114 | ≥14 | 263-287 | 33-36 | 100℃ |

| 38M | 1220-1250 | 12.2-12.5 | ≥899 | ≥11.3 | 287-310 | 36-39 | |||

| 40M | 1250-1280 | 12.5-12.8 | ≥923 | ≥11.6 | 302-326 | 38-41 | |||

| 42M | 1280-1320 | 12.8-13.2 | ≥955 | ≥12.0 | 318-342 | 40-43 | |||

| 45M | 1320-1380 | 13.2-13.8 | ≥995 | ≥12.5 | 342-366 | 43-46 | |||

| 48M | 1370-1430 | 13.7-14.3 | ≥1027 | ≥12.9 | 366-390 | 46-49 | |||

| 50M | 1400-1450 | 14.0-14.5 | ≥1033 | ≥13.0 | 382-406 | 48-51 | |||

| 35H | 1170-1220 | 11.7-12.2 | ≥868 | ≥10.9 | ≥1353 | ≥17 | 263-287 | 33-36 | 120℃ |

| 38H | 1220-1250 | 12.2-12.5 | ≥899 | ≥11.3 | 287-310 | 36-39 | |||

| 40H | 1250-1280 | 12.5-12.8 | ≥923 | ≥11.6 | 302-326 | 38-41 | |||

| 42H | 1280-1320 | 12.8-13.2 | ≥955 | ≥12.0 | 318-342 | 40-43 | |||

| 45H | 1320-1360 | 13.2-13.6 | ≥963 | ≥12.1 | 326-358 | 41-46 | |||

| 48H | 1370-1430 | 13.7-14.3 | ≥995 | ≥12.5 | 366-390 | 46-49 | |||

| 35SH | 1170-1220 | 11.7=12.2 | ≥876 | ≥11.0 | ≥1592 | ≥20 | 263-287 | 33-36 | 150℃ |

| 38SH | 1220-1250 | 12.2=12.5 | ≥907 | ≥11.4 | 287-310 | 36-39 | |||

| 40SH | 1250-1280 | 12.5=12.8 | ≥939 | ≥11.8 | 302-326 | 38-41 | |||

| 42SH | 1280-1320 | 12.8=13.2 | ≥987 | ≥12.4 | 318-342 | 40-43 | |||

| 45SH | 1320-1380 | 13.2=13.8 | ≥1003 | ≥12.6 | 342-366 | 43-46 | |||

| 28UH | 1040-1080 | 10.4=10.8 | ≥764 | ≥9.6 | ≥1990 | ≥25 | 207-231 | 26-29 | 180℃ |

| 30UH | 1080-1130 | 10.8=11.3 | ≥812 | ≥10.2 | 223-247 | 28-31 | |||

| 33UH | 1130-1170 | 11.3=11.7 | ≥852 | ≥10.7 | 247-271 | 31-34 | |||

| 35UH | 1170-1220 | 11.7=12.2 | ≥860 | ≥10.8 | 263-287 | 33-36 | |||

| 38UH | 1220-1250 | 12.2=12.5 | ≥876 | ≥11.0 | 287-310 | 36-39 | |||

| 40UH | 1250-1280 | 12.5=12.8 | ≥899 | ≥11.3 | 302-326 | 38-41 | |||

| 28EH | 1040-1080 | 10.4=10.8 | ≥780 | ≥9.8 | ≥2388 | ≥30 | 207-231 | 26-29 | 200℃ |

| 30EH | 1080-1130 | 10.8=11.3 | ≥812 | ≥10.2 | 223-247 | 28-31 | |||

| 33EH | 1130-1170 | 11.3=11.7 | ≥876 | ≥11.0 | 247-271 | 31-34 | |||

| 35EH | 1170-1220 | 11.7=12.2 | ≥876 | ≥11.0 | 263-287 | 33-36 | |||

| 38EH | 1220-1250 | 12.2=12.5 | ≥899 | ≥11.3 | 287-310 | 36-39 | |||

| 28AH | 1040-1080 | 10.4=10.8 | ≥787 | ≥9.9 | ≥2624 | ≥33 | 207-231 | 26-29 | 230℃ |

| 30AH | 1080-1130 | 10.8=11.3 | ≥819 | ≥10.3 | 223-247 | 28-31 | |||

| 33AH | 1130-1170 | 11.3=11.7 | ≥843 | ≥10.6 | 247-271 | 31-34 | |||

The main machine for producing this magnet:

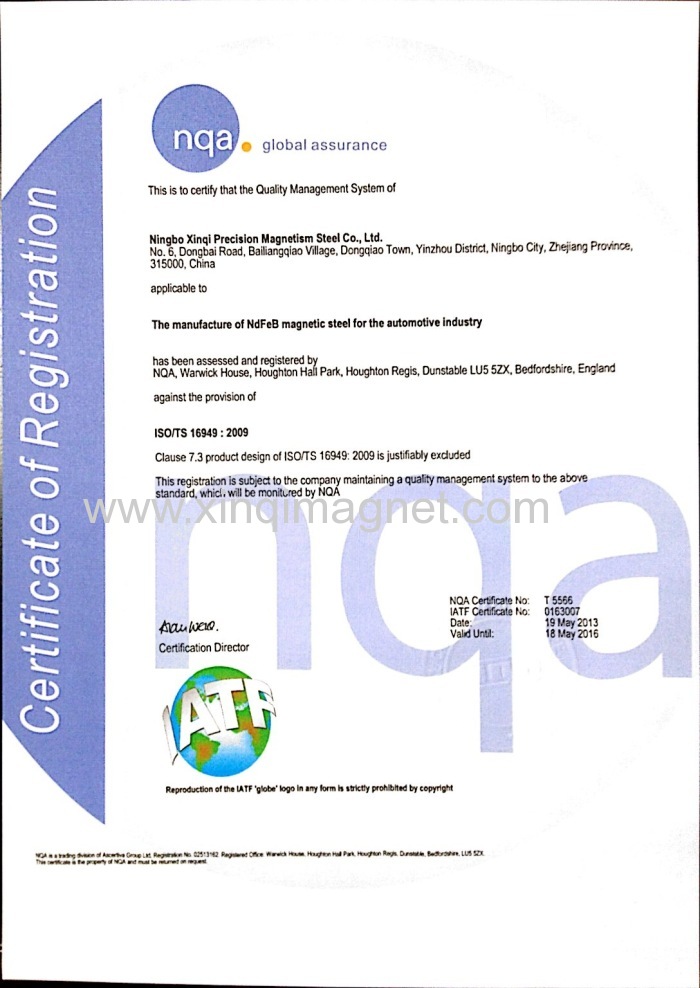

All our manufacturing procedures are operated well under ISO9001 and TS16949.

General information:

The Sintered Neodymium (NdFeB) magnet is widely used in wind generators, meters, sensors, aerospace, automotive, electronics, electro-acoustic, communications, instrumentation, medical equipment and other permanent magnetic field devices and equipment.

According to the characteristics of Sintered Neodymium (NdFeB) Block Magnet Rare Earth Magnet, it is usually need the surface treatment according to customer's requirements in order to protect magnet. Different surface coatings are available, such as Metallic Zinc, Nickel, Nickel+Nickel, Copper+Nickel, Nickel+Copper+Nickel, Gold, Black Epoxy, Nickel+Epoxy coating .

As for the size of Sintered Neodymium (NdFeB) Block Magnet Rare Earth Magnet, we could produce the magnet according your requests.