|

Ningbo Xinqi Precision Magnetism Steel Co., Ltd

|

Motor segment Neodymium Iron Boron magnet

| Price: | 0.2~0.3 USD |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

N/M/H/SH/UH/EH/AH, Segment magnet

Permanent Neodymium Iron Boron magnet Segment

The neodymium magnetis third Generation ofRare Earth magnets. It is the strongest magnet in World at present. It is mainly applied to loudspeaker, speaker parts, holding tool, motor and so on.

it is the most powerful and advanced commercialized permanent magnets today.

Characteristic of Sintered NdFeB:

1. Neodymium magnets are hard, brittle and easily corrode.

2. Neodymium magnets lose -0.09 ~ -0.13% of Br/ ° C. They areworking stability under 80 ° C for low Hci and can reach 200 ° Chighest working temperature for high Hci.

3. Excellent strength value . The highest (BH)max reaches up to 52MGOe .

4. Strip casting and HDDR technology allows us to make high performance NdFeB over N52 possible.

5. Surface treatments have been developed that allow them tobe used in most applications. The treatments include gold, nickel, zincand tin plating and epoxy resin coating.

Sintered Neodymium magnets are the most powerful permanent magnetic materials available at present, they possessing high energy ranging from 31 MGOe to 53MGOe and wonderful coercive force. As the third generation of the Rare Earth permanent Neodymium magnets, Neodymium magnets are less brittle than SmCo magnet.

Sintered Neodymium magnets have been widely used in the applications of high performance stepper, DC, servo, and linear motors, actuators, loudspeakers, headphones, instrumentation, switches, relays, magnetic imaging for medical and geophysical applications, holding systems, magnetic bearings, magnetic couplings, hard disk drives, etc..

Neodymium magnets have high remanence, high coercive force, high energy product, and high performance /cost, currently they are the stromgest magnets available magnets in the world.

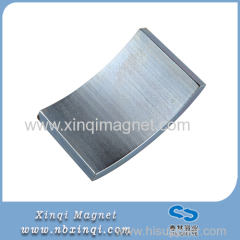

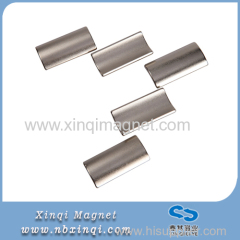

Product picture:

Features:

1) Segment magnet

2) Size: According to customer's require

3) Grade: N/M/H/SH/UH/EH/AH

4) Coating: Nickle (thickness ≥15μm) Ni+Cu+Ni 3 Layer coating, the BEST coating available

5) Magnetized Direction: through diameter

6) Salt spray test required

7) Lead time: 12-15days

8) ISO/TS16949 passed

Packing:

Inner packing: small white box, place plastic between each magnets

Outer packing: Carton with OPP bag

Properti

| Sintered Nd FeB magnetic properties | |||||||||

| (Hcb) | (Hcj) | (BH)max | Max Working | ||||||

| Grade | mT | kGs | kA/m | kOe | kA/m | kOe | kJ/m³ | MGOe | Tempt(TW)℃ |

| N35 | 1170-1220 | 11.7-12.2 | ≥868 | ≥10.9 | ≥955 | ≥12 | 263-287 | 33-36 | 80℃ |

| N38 | 1220-1250 | 12.2-12.5 | ≥899 | ≥11.3 | 287-310 | 36-39 | |||

| N40 | 1250-1280 | 12.5-12.8 | ≥907 | ≥11.4 | 302-326 | 38-41 | |||

| N42 | 1280-1320 | 12.8-13.2 | ≥915 | ≥11.5 | 318-342 | 40-43 | |||

| N45 | 1320-1380 | 13.2-13.8 | ≥923 | ≥11.6 | 342-366 | 43-46 | |||

| N48 | 1380-1420 | 13.8-14.2 | 366-390 | 46-49 | |||||

| N50 | 1400-1450 | 14.0-14.5 | ≥796 | ≥10.0 | ≥876 | ≥11 | 382-406 | 48-51 | |

| N52 | 1430-1480 | 14.3-14.8 | 398-422 | 50-53 | |||||

| 35M | 1170-1220 | 11.7-12.2 | ≥868 | ≥10.9 | ≥1114 | ≥14 | 263-287 | 33-36 | 100℃ |

| 38M | 1220-1250 | 12.2-12.5 | ≥899 | ≥11.3 | 287-310 | 36-39 | |||

| 40M | 1250-1280 | 12.5-12.8 | ≥923 | ≥11.6 | 302-326 | 38-41 | |||

| 42M | 1280-1320 | 12.8-13.2 | ≥955 | ≥12.0 | 318-342 | 40-43 | |||

| 45M | 1320-1380 | 13.2-13.8 | ≥12.5 | 342-366 | 43-46 | ||||

| 48M | 1370-1430 | 13.7-14.3 | ≥1027 | ≥12.9 | 366-390 | 46-49 | |||

| 50M | 1400-1450 | 14.0-14.5 | ≥1033 | ≥13.0 | 382-406 | 48-51 | |||

| 35H | 1170-1220 | 11.7-12.2 | ≥868 | ≥10.9 | ≥1353 | ≥17 | 263-287 | 33-36 | 120℃ |

| 38H | 1220-1250 | 12.2-12.5 | ≥899 | ≥11.3 | 287-310 | 36-39 | |||

| 40H | 1250-1280 | 12.5-12.8 | ≥923 | ≥11.6 | 302-326 | 38-41 | |||

| 42H | 1280-1320 | 12.8-13.2 | ≥955 | ≥12.0 | 318-342 | 40-43 | |||

| 45H | 1320-1360 | 13.2-13.6 | ≥963 | ≥12.1 | 326-358 | 41-46 | |||

| 48H | 1370-1430 | 13.7-14.3 | ≥995 | ≥12.5 | 366-390 | 46-49 | |||

| 35SH | 1170-1220 | 11.7=12.2 | ≥876 | ≥11.0 | ≥1592 | ≥20 | 263-287 | 33-36 | 150℃ |

| 38SH | 1220-1250 | 12.2=12.5 | ≥907 | ≥11.4 | 287-310 | 36-39 | |||

| 40SH | 1250-1280 | 12.5=12.8 | ≥939 | ≥11.8 | 302-326 | 38-41 | |||

| 42SH | 1280-1320 | 12.8=13.2 | ≥987 | ≥12.4 | 318-342 | 40-43 | |||

| 45SH | 1320-1380 | 13.2=13.8 | ≥1003 | ≥12.6 | 342-366 | 43-46 | |||

| 28UH | 1040-1080 | 10.4=10.8 | ≥764 | ≥9.6 | ≥1990 | ≥25 | 207-231 | 26-29 | 180℃ |

| 30UH | 1080-1130 | 10.8=11.3 | ≥812 | ≥10.2 | 223-247 | 28-31 | |||

| 33UH | 1130-1170 | 11.3=11.7 | ≥852 | ≥10.7 | 247-271 | 31-34 | |||

| 35UH | 1170-1220 | 11.7=12.2 | ≥860 | ≥10.8 | 263-287 | 33-36 | |||

| 38UH | 1220-1250 | 12.2=12.5 | ≥876 | ≥11.0 | 287-310 | 36-39 | |||

| 40UH | 1250-1280 | 12.5=12.8 | ≥899 | ≥11.3 | 302-326 | 38-41 | |||

| 28EH | 1040-1080 | 10.4=10.8 | ≥780 | ≥9.8 | ≥2388 | ≥30 | 207-231 | 26-29 | 200℃ |

| 30EH | 1080-1130 | 10.8=11.3 | ≥812 | ≥10.2 | 223-247 | 28-31 | |||

| 33EH | 1130-1170 | 11.3=11.7 | ≥876 | ≥11.0 | 247-271 | 31-34 | |||

| 35EH | 1170-1220 | 11.7=12.2 | ≥11.0 | 263-287 | 33-36 | ||||

| 38EH | 1220-1250 | 12.2=12.5 | ≥899 | ≥11.3 | 287-310 | 36-39 | |||

| 28AH | 1040-1080 | 10.4=10.8 | ≥787 | ≥9.9 | ≥2624 | ≥33 | 207-231 | 26-29 | 230℃ |

| 30AH | 1080-1130 | 10.8=11.3 | ≥819 | ≥10.3 | 223-247 | 28-31 | |||

| 33AH | 1130-1170 | 11.3=11.7 | ≥843 | ≥10.6 | 247-271 | 31-34 | |||

es:

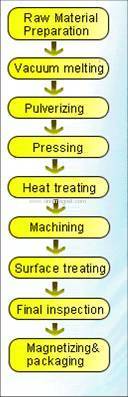

Production process: